Processing methods for stainless steel flanges and various rust removal methods for pipe fitting elbows

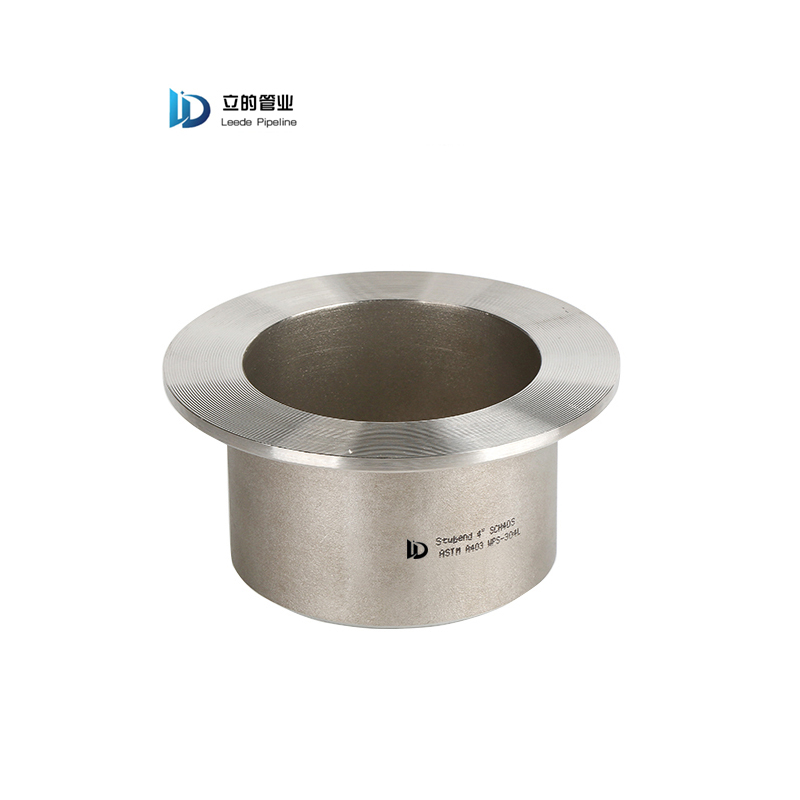

There are also many ways to process stainless steel flanges. Many of them still belong to the category of mechanical processing, and the most commonly used methods are stamping, forging, roller processing, rolling, bulging, stretching, bending, and combined processing.

Stainless steel flanges have corresponding technical requirements and technical parameters in production and use, and are produced and processed in accordance with corresponding methods and methods:

1. The welding process of the butt welding flange needs to be adopted, and the butt welding seam of the circular ring should be a full penetration welding seam.

2. The steel plates used in the production of stainless steel flanges should be inspected by special waves to ensure that there are no delamination defects, good quality and performance problems should be determined, and should be produced and inspected in accordance with the corresponding quality requirements to ensure that the steel plates produced and used have no quality problems.

3. Install a flange in the pipelines that need to be connected. Low-pressure pipelines can use wire flanges, and welding flanges with pressures above 4 kg. Add a sealing point between the two butt welding flanges and tighten them with bolts. Flanges for different pressures have different thicknesses and use different bolts.

4. The steel should be cut into strips along the rolling direction, bent and butt welded into a ring shape, and the surface of the steel should form a ring cylinder. When producing halogen flanges, steel plates must not be directly machined into neck flanges, and corresponding processes must be used for production and processing.

5. Flange is a disc-shaped part, which is more common in pipeline engineering. Flanges are used in pairs. In pipeline engineering, flanges are mainly used for the connection of pipelines.

6. The butt welds of the rings should be subjected to post-weld heat treatment and radiographic or sonic flaw detection. Butt welding flanges are produced and processed using corresponding welding standards and technologies, in line with my country's corresponding production standards and requirements.

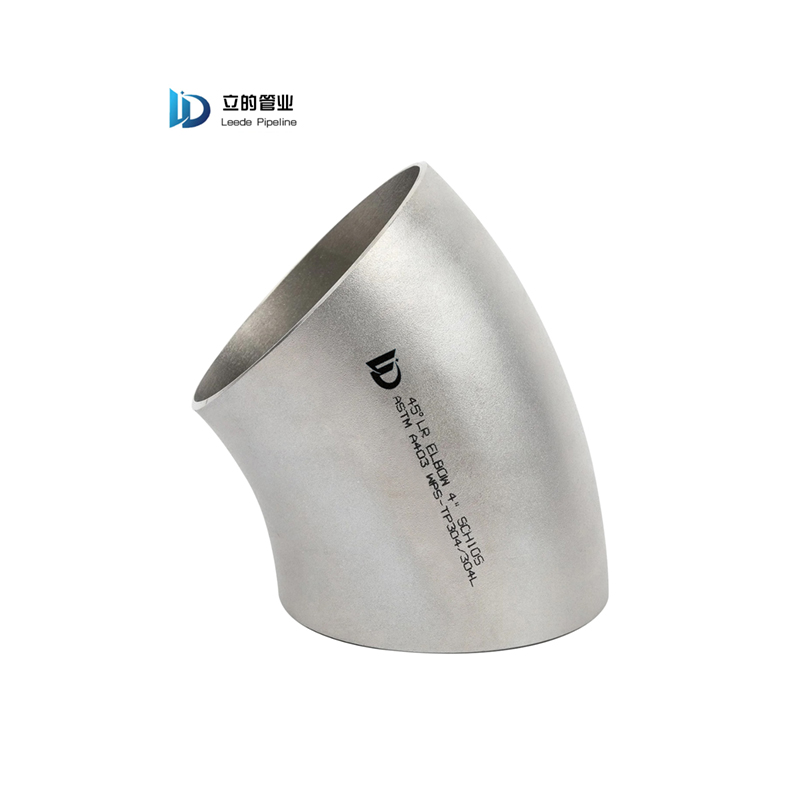

Briefly describe the rust removal method of stainless steel pipe fittings elbow:

1. Radiation rust removal: Radiation rust removal uses a high-power motor to start the jet blades to rotate at high speed, so that abrasives such as steel shot, steel sand, iron wire segments, minerals, etc. are radiated on the surface of the straight seam steel pipe under the powerful centrifugal force of the motor. , not only can remove oxides, rust and dirt, but also can achieve the required uniform roughness under the action of severe abrasive impact and friction, which is a relatively complete rust removal method. After large-diameter flange radiation rust removal, it can not only expand the physical adsorption function of the pipe surface, but also enhance the mechanical adhesion function between the layer and the pipe surface.

2. Tool rust removal: Large-diameter flanges mainly use tools such as wire brushes to polish the surface of the steel to remove loose scale, rust, welding slag, etc. The rust removal of hand tools can reach Sa2 level, and the rust removal of power tools can reach Sa3 level. If the surface of the steel is adhered to the iron oxide scale, the rust removal effect of the tool will not be ideal, and the depth of the anchor pattern that cannot meet the construction requirements is a relatively primitive method. rust removal method.

3. Pickling: Pipe fitting elbows are generally pickled by chemical and electrolytic methods. Pipes only use chemical pickling, which can remove oxide scale, rust, and old coatings. Sometimes it can be used as a reprocessing agent after sandblasting and rust removal. Disposal. Although chemical cleaning can make the surface reach a certain degree of cleanliness and roughness, its anchor lines are shallow and it is easy to cause pollution to the surrounding environment. This method is not very recommended.

4. Cleaning: Large-diameter flanges use solvents and emulsions to clean the steel surface to remove oil, grease, dust, smoothers and similar substances. However, it cannot remove rust, oxide scale, welding, etc. on the steel surface. Therefore, in the defense It is only used as an auxiliary method during operation and is also one of the simpler maintenance methods.