Is the eccentric size of the stainless steel pipe fittings at the pump inlet installed flat up or down?

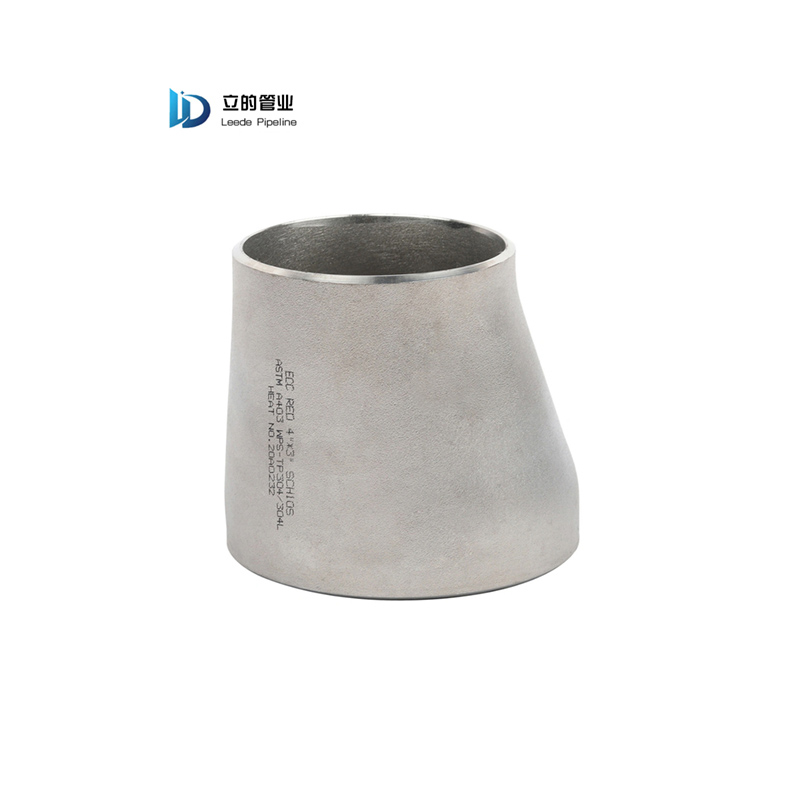

What is the function of the big and small heads in stainless steel pipe fittings? It is used to change the size of the pipe diameter. So what is the use of changing the diameter of the pipe at the inlet and outlet of the pump? The main purpose is to reduce the flow velocity of the medium in the pipeline and reduce the flow velocity to reduce the friction when the medium flows in the pipeline.

The horizontal eccentric reducer at the inlet of the centrifugal pump generally adopts a top-flat arrangement, but when the reducer is directly connected to an upwardly bent elbow, a bottom-flat arrangement can be used. The reducer should be located close to the pump inlet. The reason for the flat top installation is to prevent gas from accumulating in the eccentric reducer and entering the centrifugal pump, causing cavitation damage to the pump. When the inlet diameter of a horizontal suction centrifugal pump is changed, the pipe entering the pump from bottom to top should be installed with a top level, and the pipe entering the pump from top to bottom should be installed with a bottom level (to prevent gas from accumulating at the pump port, a top level installation is also used). The medium contains impurities. And if the suction speed is lower than the impurity settling speed, it should be installed flat on the bottom. The principle is not to form air pockets.

Regarding the installation of the eccentric and large heads on the inlet pipe of the end-suction centrifugal pump (that is, the pump inlet is a horizontal inlet), in the textbook on pump piping standards, it is stipulated as follows: the orientation of the eccentric reducer diameter on the horizontal pipe (horizontal part is upward or downward), it is determined by whether a liquid bag or air bag appears (divided into two situations):

1. When the medium enters the pump from top to bottom, it is installed with a flat-bottomed eccentric large and small head so that no liquid bag appears;

2. When the medium enters the pump from bottom to top, it is installed with a flat and eccentric head to avoid air bags;

To sum up, it is generally "the top is flat when going up, and the top is flat when going down."

To understand this reason, we must first understand a knowledge point: cavitation phenomenon. Of course, if you are only doing industrial installation, you don’t need to know so much, because each pump manufacturer’s instructions have complete and correct installation methods, and you only need to follow the drawings.