Five major advantages of stainless steel pipe fittings stamping elbows in the chemical pipeline industry

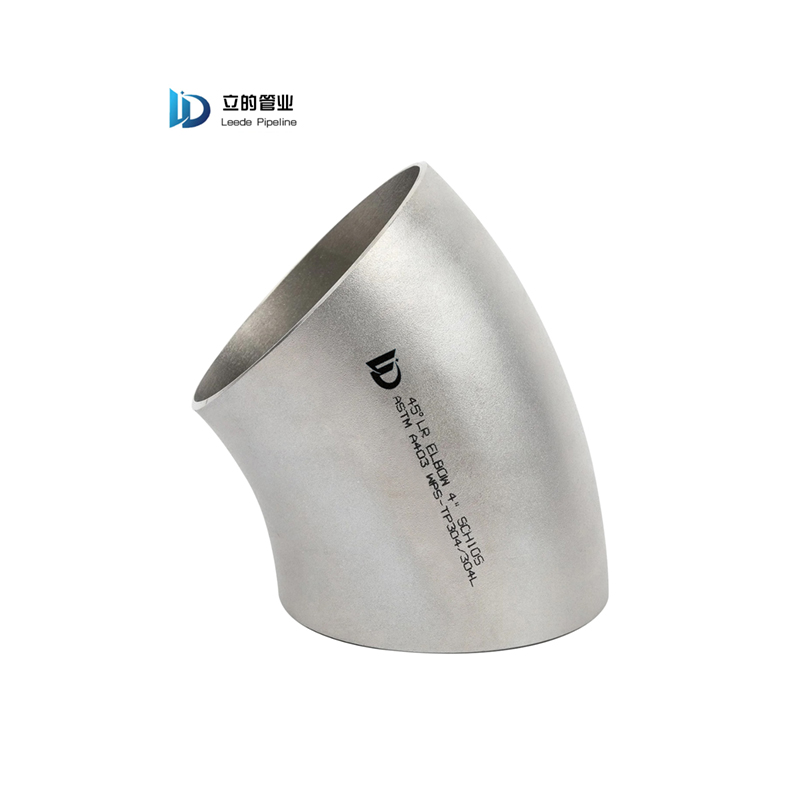

Stainless steel pipe fittings stamped elbows are suitable for piping systems in petroleum, chemical, hydropower, construction and boiler industries. The reason why stainless steel stamped elbows are widely used in all walks of life and their advantages are generally recognized by everyone, please share them. 5 advantages of stainless steel stamping elbows:

1. Stainless steel stamping elbow has high stamping strength and stiffness due to the cold deformation and hardening effect of the material during stamping.

2. Stainless steel stamping elbow Because the mold determines the size and shape accuracy of the stainless steel stamping elbow.

3. The production speed of stainless steel stamping elbow is relatively good, and the operation is simple, making it easy to realize mechanization and automation. Because stamping relies on stamping molds and stamping equipment to complete processing and production, the number of strokes of an ordinary press is about dozens of times per minute, and high-speed pressure can reach hundreds or even thousands of times per minute. Each stamping stroke may be one stamping parts.

4. Stainless steel stamping elbows have less scrap material, so there is less waste of raw materials, and no other heating equipment is needed, so it is a material-saving and energy-saving processing method.

5. The range of sizes that can be processed by stainless steel stamping elbows is small.

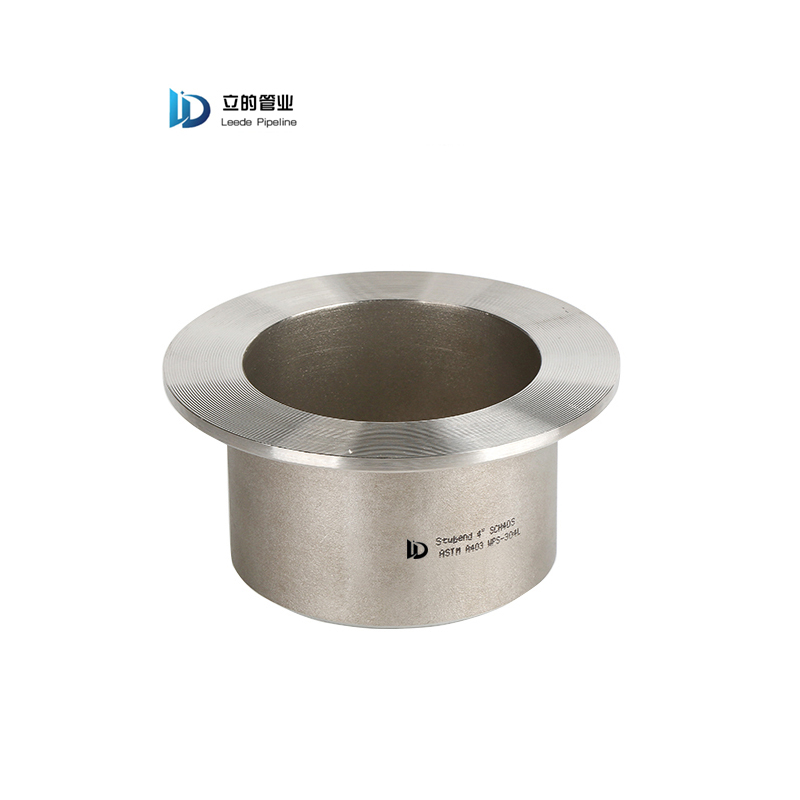

Stainless steel elbow is the weak link in the piping system. The performance of the pipeline is mainly determined by the working ability of the stainless steel elbow. The working ability of stainless steel elbow is related to its stress state. Calculation and on-site measurement of the working stress of pipe fittings found that the arc starting point of the stainless steel elbow is particularly sensitive to external loads. Excluding internal pressure and self-weight, the external loads are mainly due to the thermal expansion of the pipe metal during the starting process of the pipe system, vibration of the pipe system and supports and hangers. Additional external loads caused by work abnormalities, etc. When the arcing section of the stainless steel elbow is a butt weld, these changing external loads will cause the weld to be in a complex stress state, seriously weakening the strength of the weld, reducing the working ability of the stainless steel elbow, and shortening the service life of the stainless steel elbow. Therefore, from the design point of view Consider changing the interface of the welded stainless steel elbow to a straight section, that is, designing a stainless steel elbow with a straight section to facilitate the welding joint, improve the quality of the welding joint, and improve the service life of the stainless steel elbow.