Bending performance and characteristics of thin-walled flat elbows in stainless steel pipe fittings

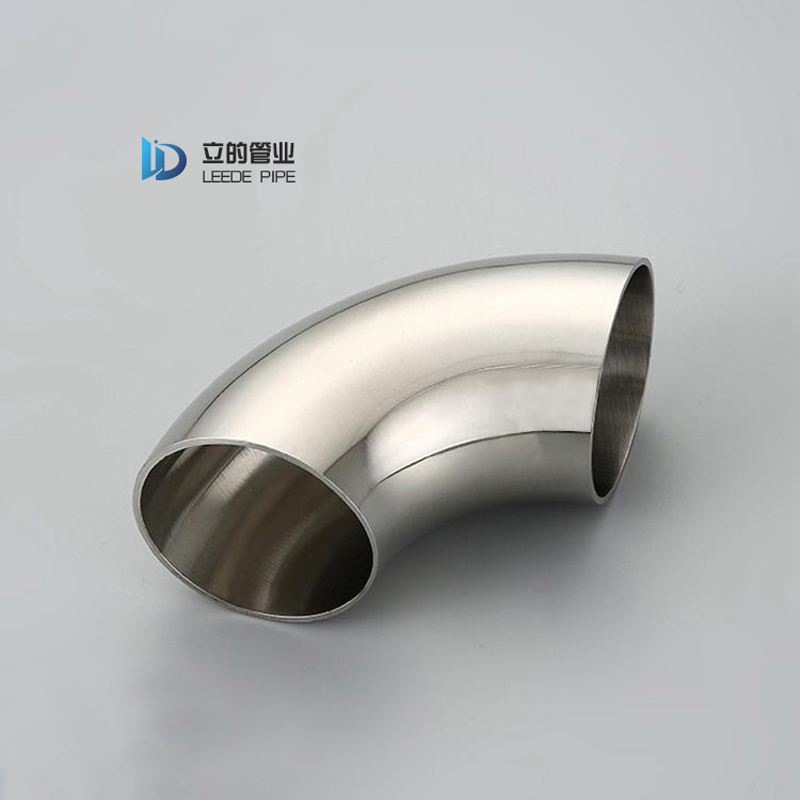

Thin-walled elbows in stainless steel pipe fittings are a common pipe connection component. They are generally sanitary grade. The grooves are generally flat and have excellent corrosion resistance and pressure resistance. It is widely used in pipeline systems in chemical, petroleum, natural gas, paper and other industries. The bending characteristics of stainless steel thin-walled elbows will be introduced below.

Deformation characteristics of thin-walled elbow during bending process:

The deformation characteristics of stainless steel elbows that occur during the bending process are mainly reflected in the following aspects:

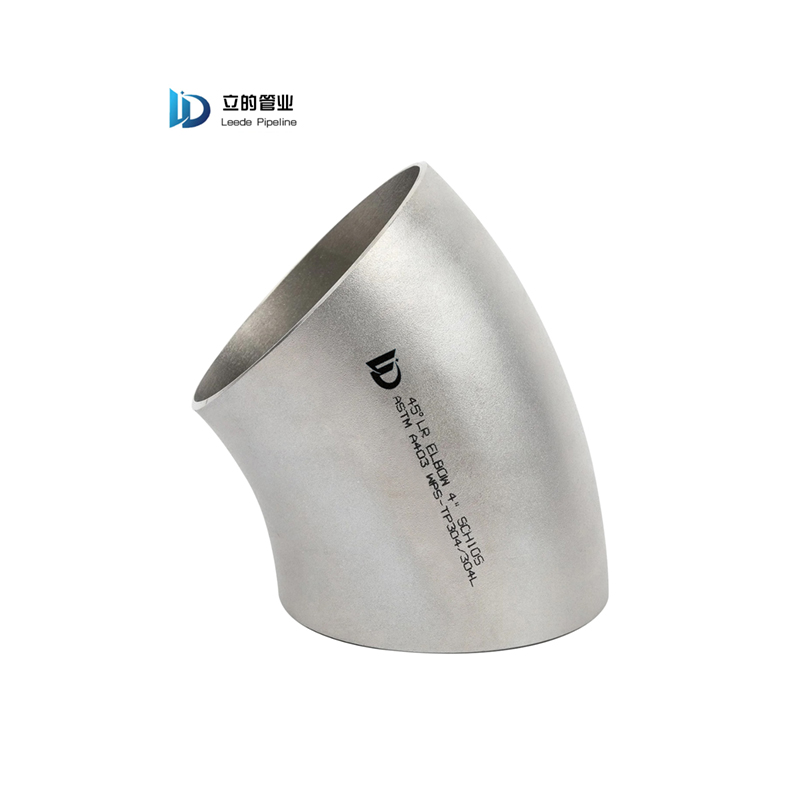

First, the deformation of the inner and outer diameters produced during the bending process is small. Due to its thin-walled structure, the inner and outer diameters of stainless steel thin-walled elbows will change during the bending process. It has been proven by practice that the inner diameter deformation rate of stainless steel thin-walled elbows is usually controlled within 2%, and the outer diameter deformation rate is usually controlled within 4%.

Secondly, the cross-sectional shape changes produced during the bending process are small. The stainless steel thin-walled elbow is subjected to tensile and compressive forces during the bending process, causing its cross-sectional shape to change. However, due to the excellent properties of its material, the cross-sectional shape of stainless steel thin-walled elbows changes less and can maintain good fluid channels.

The tube wall thickness changes produced during the bending process are small. The pipe wall thickness of stainless steel thin-wall elbow will change during the bending process, but the range of change is relatively small. After process control, the pipe wall thickness variation of stainless steel thin-walled elbows is usually controlled within 10%.

Stress distribution during bending:

During the bending process, the pipe wall of the stainless steel thin-walled elbow is subject to stress, and its stress distribution characteristics are as follows:

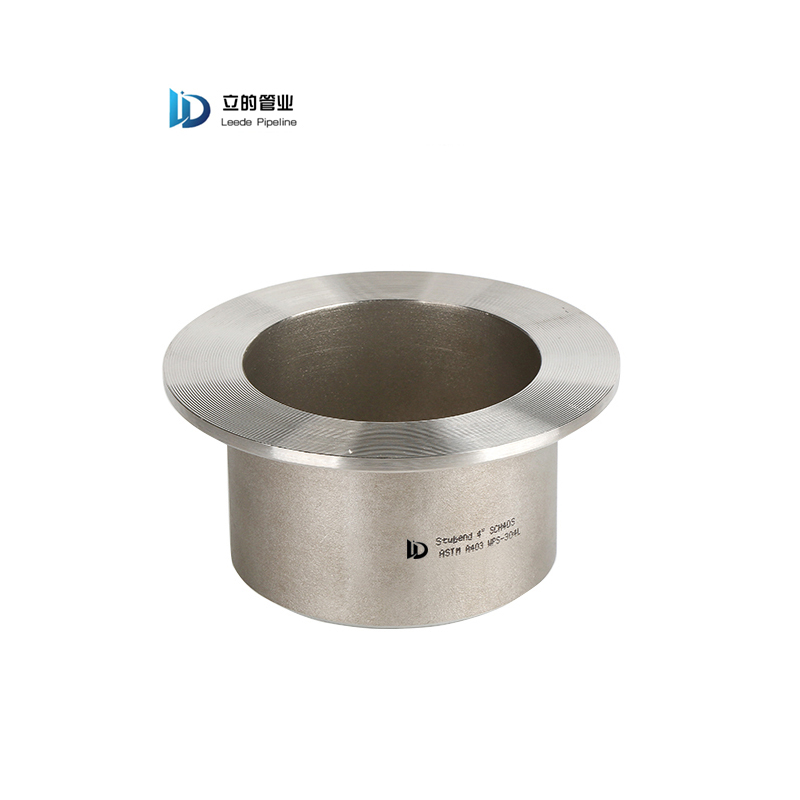

First, the stress concentration area generated during the bending process is 1.5 times away from the bending radius. The larger the bending radius of the stainless steel thin-walled elbow, the smaller the distance between the stress concentration area and the bending radius.

Secondly, the stress distribution during bending is symmetrical. During the bending process of the stainless steel thin-walled elbow, the stress distribution on the inner and outer diameters is symmetrical. This symmetrical feature ensures the stability of the piping system and the smooth flow of fluid channels.

The stress change rate generated during the bending process is large. During the bending process of the stainless steel thin-walled elbow, due to the action of tensile force and compression force, the stress change rate is large. In order to ensure the safe operation of the pipeline system, the stress during the bending process must be fully calculated and controlled.